The Coriolis measuring principle is used in a wide range of different branches of industry, such as the life sciences, chemicals, petrochemicals, oil and gas, food, and – no less importantly – in custody transfer applications. Coriolis flowmeters can measure virtually all fluids: cleaning agents, solvents, fuels, crude oil, vegetable oils, animal fats, latex, silicon oils, alcohol, fruit solutions, toothpaste, vinegar, ketchup, mayonnaise, gases or liquefied gases.

The flowmeter has premium accuracy and robustness. It also has an ultra-compact transmitter.

Predecessor model: Promass 80F, Promass 83F

Max.

measurement error

Mass flow (liquid): ±0.1 % (standard), 0.05 %

(option)

Volume flow (liquid): ±0.1 %

Mass flow (gas): ±0.25 %

Density (liquid): ±0.0005 g/cm³

Measuring

range

0 to 2,200,000 kg/h (0 to 80,840 lb/min)

Medium

temperature range

Standard: –50 to +150 °C (–58 to +302 °F)

Option: –50 to +240 °C (–58…+464 °F)

Max.

process pressure

PN 100, Class 600, 63K

Wetted

materials

Measuring tube: 1.4539 (904L); 1.4404

(316/316L); Alloy C22, 2.4602 (UNS N06022)

Connection: 1.4404 (316/316L); Alloy C22, 2.4602 (UNS

N06022)

The ultimate flowmeter provides premium accuracy, robustness and an easily accessible compact transmitter.

Predecessor model: Promass 80F, Promass 83F, Promass 84F

Max. measurement

error

Mass flow (liquid): ±0.10 % (standard), 0.05 %

(option)

Volume flow (liquid): ±0.10 %

Mass flow (gas): ±0.25 %

Density (liquid): ±0.0005 g/cm³

Measuring range

0 to 2,200,000 kg/h (0 to 80,840 lb/min)

Medium

temperature range

Standard: –50 to +150 °C (–58…+302 °F)

Option: –50 to +240 °C (–58…+464 °F)

High temperature option: –50 to +350 °C

(–58…+662 °F)

Option: –196 to +150 °C (–320 to +302 °F)

Max. process

pressure

PN 100, Class 600, 63K

Wetted materials

Measuring tube: 1.4539 (904L); 1.4404

(316/316L); Alloy C22, 2.4602 (UNS N06022)

Connection: 1.4404 (316/316L); Alloy C22,

2.4602 (UNS N06022); 1.4301 (F304)

The ultimate flowmeter provides premium accuracy, robustness and works as a remote version with up to 4 I/Os

Predecessor model: Promass 80F, Promass 83F, Promass 84F

Max. measurement

error

Mass flow (liquid): ±0.10 % (standard), 0.05 %

(option)

Volume flow (liquid): ±0.10 %

Mass flow (gas): ±0.25 %

Density (liquid): ±0.0005 g/cm³

Measuring range

0 to 2,200,000 kg/h (0 to 80,840 lb/min)

Medium

temperature range

Standard: –50 to +150 °C (–58…+302 °F)

Option: –50 to +240 °C (–58…+464 °F)

High temperature option: –50 to +350 °C

(–58…+662 °F)

Option: –196 to +150 °C (–320 to +302 °F)

Max. process

pressure

PN 100, Class 600, 63K

Wetted materials

Measuring tube: 1.4539 (904L); 1.4404

(316/316L); Alloy C22, 2.4602 (UNS N06022)

Connection: 1.4404 (316/316L); Alloy C22,

2.4602 (UNS N06022); 1.4301 (F304)

This budget-saving flow meter comes with an ultra-compact transmitter.

Predecessor model: Promass 80E, Promass 83E, Proline Promass E 100 / 8E1B

Max. measurement

error

Mass flow (liquid): ±0.15 % (standard), ±0.10

% (option)

Volume flow (liquid): ±0.15 %

Mass flow (gas): ±0.50 %

Density (liquid): ±0.0005 g/cm³

Measuring range

0 to 180,000 kg/h (0 to 6600 lb/min)

Medium

temperature range

–40 to +150 °C (–40 to +302°F)

Max. process

pressure

PN 100, Class 600, 63K

Wetted materials

Measuring tube: 1.4539 (904L)

Connection: 1.4404 (316/316L)

This budget-friendly Coriolis flowmeter has an easily accessible compact transmitter.

Predecessor model: Promass 80E, Promass 83E

Max. measurement

error

Mass flow (liquid): ±0.15 % (standard), ±0.10

% (option)

Volume flow (liquid): ±0.15 %

Mass flow (gas): ±0.50 %

Density (liquid): ±0.0005 g/cm³

Measuring range

0 to 180,000 kg/h (0 to 6615 lb/min)

Medium

temperature range

–40 to +150 °C (–40 to +302 °F)

Max. process

pressure

PN 100, Class 600, 63K

Wetted materials

Measuring tube: 1.4539 (904L)

The mid-range Coriolis flowmeter is available in a remote version, and has up to 4 I/Os

Predecessor model: Promass 80E, Promass 83E

Max.

measurement error

Mass flow (liquid): ±0.15 % (standard), ±0.10

% (option)

Volume flow (liquid): ±0.15 %

Mass flow (gas): ±0.50 %

Density (liquid): ±0.0005 g/cm³

Measuring

range

0 to 180,000 kg/h (0 to 6615 lb/min)

Medium

temperature range

–40 to +150 °C (–40 to +302 °F)

Max.

process pressure

PN 100, Class 600, 63K

Wetted

materials

Measuring tube: 1.4539 (904L)

Connection: 1.4404 (316/316L)

This innovative specialist flowmeter for complex applications has an easily accessible compact transmitter.

Max. measurement

error

Mass flow (liquid): ±0.10 % (standard), 0.05 %

(option)

Volume flow (liquid): ±0.10 %

Mass flow (gas): ±0.25 %

Density (liquid): +/-0.2 kg/m³ (standard),

+/-0.1 kg/m³ (option)

Measuring range

0 to 2,400,000 kg/h (0 to 88183 lb/min)

Medium

temperature range

Standard: –50 to +205°C (–58 to +401 °F)

Option: –196 to +150 °C (–321 to +302 °F)

Max. process pressure

PN 100, Class 600, 63K

Wetted materials

Measuring tube: 1.4404 (316/316L); stainless

steel for cryogenic applications

Connection: 1.4404 (316/316L)

A combination of in-line viscosity and flow measurement, easily accessible compact transmitter.

Predecessor model: Promass 80I, Promass 83I

Max. measurement

error

Mass flow (liquid): ±0.10 %

Volume flow (liquid): ±0.10 %

Mass flow (gas): ±0.50 %

Density (liquid): ±0.0005 g/cm³

Measuring range

0 to 180,000 kg/h (0 to 6600 lb/min)

Medium

temperature range

–50 to +150 °C (–58 to +302 °F)

Max. process

pressure

PN 100, Class 600, 63K

Wetted materials

Measuring tube: Titanium grade 9

Connection: Titanium grade 2

This easy-to-use flow meter minimizes the total cost of ownership.

Predecessor model: Promass 40E

Max. measurement

error

Mass flow (liquid): ±0.5 % (standard), ±0.15 %

(option)

Mass flow (gas): ±0.75 %

Measuring range

0 to 180,000 kg/h (0 to 6615 lb/min)

Medium

temperature range

–40 to +150 °C (–40 to +302 °F)

Max. process

pressure

PN 40, Class 300, 40K

Wetted materials

Measuring tube: 1.4539 (904L)

Connection: 1.4404 (316/316L)

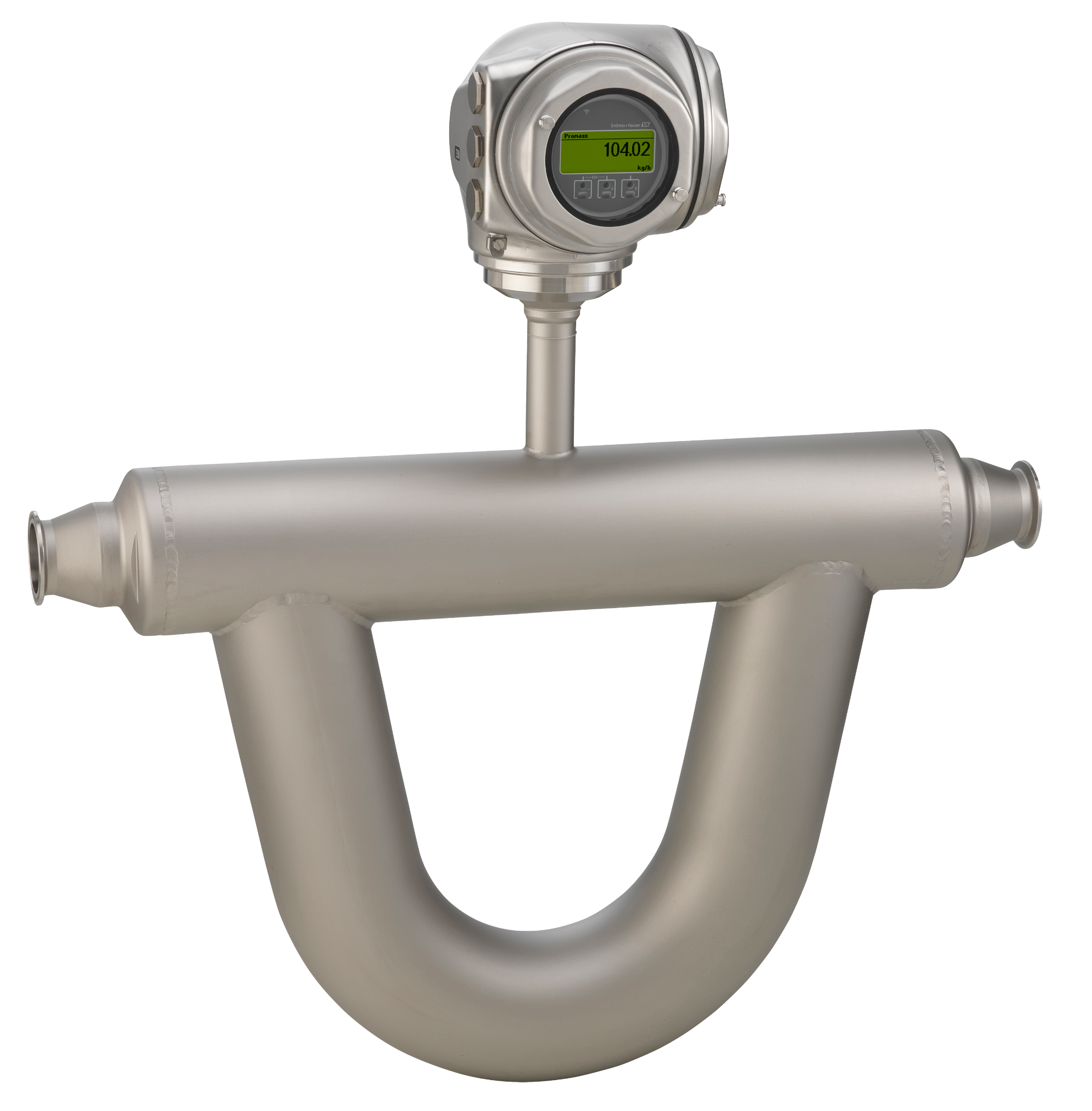

Each Coriolis flowmeter has one or more measuring tubes which an exciter causes to oscillate artificially. As soon as the fluid starts to flow in the measuring tube, additional twisting is imposed on this oscillation due to the fluid‘s inertia. Two sensors detect this change of the tube oscillation in time and space as the “phase difference.” This difference is a direct measure of the mass flow.

In addition, the fluid density can also be determined from the oscillation frequency of the measuring tubes. The temperature of the measuring tube is also registered to compensate thermal influences. The process temperature derived from this is available as an additional output signal.