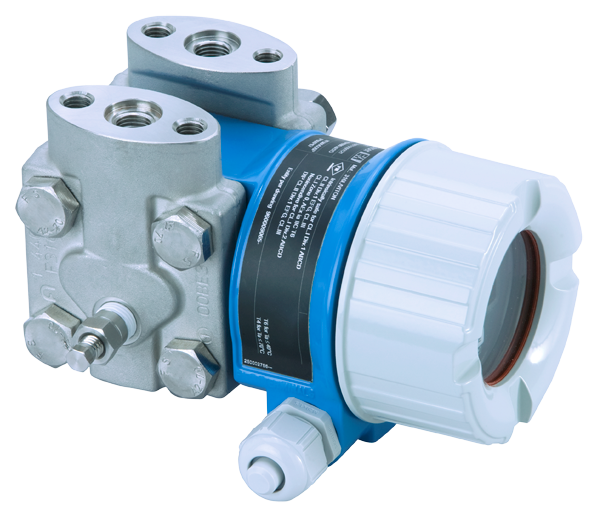

Differential pressure transmitters with piezoresistive pressure sensors and welded metallic membrane or electronic dp or diaphragm seal is used mostly in the process industry. Deltabar offers continuous level measurement in liquids as well as volume or mass flow measurement using primary elements. It is also possible to do filter monitoring with the differential pressure transmitter. Check out the broad range of Deltabar devices and click on the button below.

Metal sensor for measuring the pressure differences.

Silicon cell: The operating pressure deflects the process isolating diaphragm and a fill fluid transfers the pressure to a resistance bridge (semiconductor technology). The pressure-dependent change in the bridge output voltage is measured and evaluated.

Diaphragm seal: The operating pressure acts on the process isolating diaphragm of the diaphragm seal and is transferred to the process isolating diaphragm of the sensor by a fill fluid.