Vibronic point level detection offers safe overfill prevention in liquids and bulk solids in every industry. The second line of defense guarantees the highest degree of safety and availability of the switches. Liquiphant stands for reliable switching unaffected by: changing media properties, turbulences, foam, vibrations or build-up. In silos containing fine-grained or powdery solids Soliphant is the perfect match. For more information click on the button below.

Level switch for point level measurement for all liquid media.

Predecessor model: Liquiphant M FTL51, Liquiphant M FTL50

Stainless steel compact designed point level switch for application in liquids.

Predecessor model: Pump Protection FTW360, Liquiphant T FTL260, Liquiphant T FTL20

Compact vibronic type point level switch for liquid applications in all industries.

Point level Switch for liquid applications with extension tubes.

Predecessor model: CS1103, CS1113, CS1203, CS1213, CS1603, CS1613, FTL51K, FTL360, FTL361, FDL30, FDL31, FTL365, FTL366, FDL35, FDL36 Successor model: Liquiphant FTL51B

VIbronic type level switch for basic applications minimizes complexities in your plant.

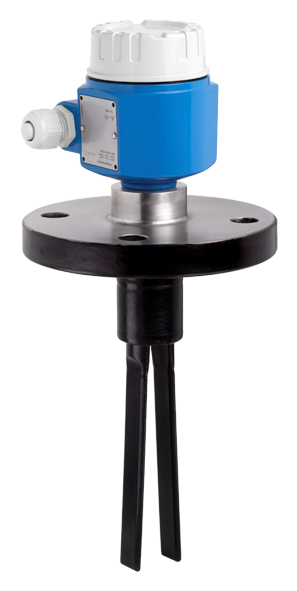

Point level switch for level measurement in fine-grained bulk solids. Also available for Hazardous area.

Predecessor model: Soliphant II FTM30, Soliphant II FTM30D, Soliphant II FTM30S, HTM10E, HTM10A, FTM30DR, Soliphant T FTM260.

Vibronic Point level switch with extension tube for level measurement in fine-grained bulk solids. Also available for Hazardous area.

Predecessor model: Soliphant II FTM31, Soliphant II FTM31D, Soliphant II FTM31S, HTM10E, HTM10A, FTM31DR

For point level detection in liquids a sensor in form of a tuning fork is excited at its resonant frequency. The drive works piezoelectrically. The oscillating frequency changes as the fork enters the medium. The change is analyzed and translated into a switching signal.

In solids a one-rod sensor is excited at its resonant frequency. The drive works piezoelectrically. The amplitude changes as the fork enters the medium. The change is also analyzed and translated into a switching signal.