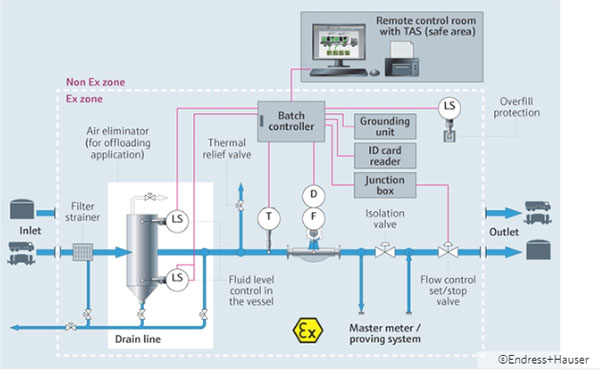

Our loading and unloading metering skid for Oil and Gas, equipped with Endress+Hauser custody transfer certified Promass Coriolis flow meter, comply with and even exceed custody transfer accuracy as per OIML R 117, while providing lower pressure drop, high flow rate capacity and smaller footprint. Maintenance is optimized, with no moving parts, Heartbeat technology for verification according to IEC 61511-1, diagnostics to Namur NE 107, and predictive maintenance features.

For all your Oil and Gas custody transfer applications in trucks and railcars, our worldwide network of metering experts is available throughout the asset lifecycle, from front-end engineering design to operations and maintenance.