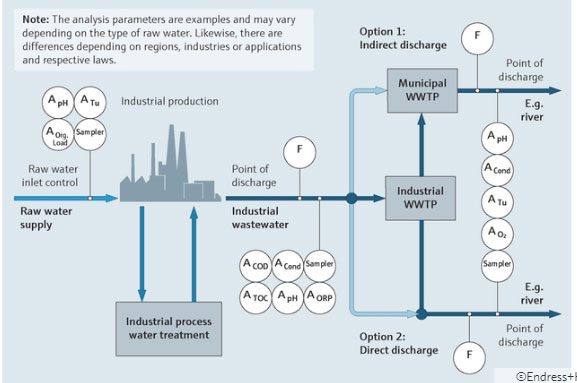

For chemical plants, we have developed measuring panels that precisely monitor wastewater quality. With the measured values supplied, you can safely and efficiently treat the wastewater to exactly the level you need for your purposes. The panels provide all readings in one central location, are easy to install and commission, and are tailored to your exact plant. What's more, they are low-maintenance and, if you wish, you can take advantage of Endress+Hauser's expert global support.